Seeed were kind enough to offer me a coupon towards their Seeed-Fusion PCB service. I had a design ready which I had recently converted from Eagle to KiCad so it seemed like an excellent opportunity to try them out.

Board pricing structure

I am a maker, building things in my spare time, so I tend to make small boards in low quantities. The SeeedFusion pricing structure is optimized for larger boards at larger volumes. However, they usually have a offer in place to encourage prototypers and makers to use their service for smaller volumes. When I ordered the offer was $9.90 for 10 boards up to 100mm by 100mm, at the time of writing the price has been reduced to $4.90.

This is an excellent deal if you want ten 100mm by 100mm boards, but it isn’t great if you just want a few small boards. 100mm by 100mm is larger than a Raspberry Pi or an Arduino. The board I had in mind was 0.8″ by 0.5″ (20.32mm x 12.7mm). The result of the special offer is that introduces a discontinuity in the pricing structure. I made the chart below to illustrate how the pricing in US dollars per square inch changes with board size and quantity by plugging different parameters into the order form.

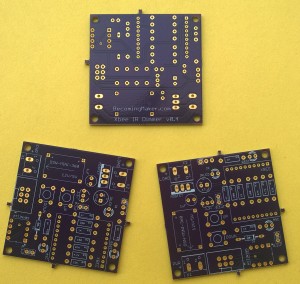

In my case ten boards would have cost $9.90 whereas 30 boards cost $11.78 so I decided I might as well go for 30 boards.

Shipping costs

Free shipping is a wonderful thing because you don’t have to factor shipping costs into your purchase decision. However SeeedFusion charges shipping even on small orders. When I order components from AliExpress I usually get free or less than $2 China Post ePacket shipping to the US for small items. It would be great if SeeedFusion could offer a similar service on small orders.

The cheapest shipping option on my one ounce order was $11.52. So even at 30 boards this doubles the price of the board. In my case this added up to $0.78 per board.

I expect the shipping costs increase as the order size increases, but you don’t get to see the shipping cost until you add an order to your cart. So making the overly simplistic assumption that shipping on all order sizes is $11.52 we get the following price chart.

Stencils

Seeed-Fusion stencils start at $19.90 which is a reasonable price. However when I added a stencil to my cart it added $32.85 to my shipping costs. The reason is that the smallest stencil is 28cm by 38cm which is larger than a letter size sheet of paper. I like using a stencil for SMD boards, but I want a nice small stencil for prototyping as I am only making one board at a time.

HASL or ENIG finish

Exposed copper pads tarnish quickly, so they need to be finished to protect them. The prices above are for HASL which is basically a layer of solder on the exposed copper. Another option is ENIG which is an electroless nickel plating covered with a thin layer of immersion gold.

ENIG is flatter than HASL and doesn’t migrate during reflow so it is a better choice for fine pitched SMD parts and strongly recommended for BGAs.

The prices above jump dramatically (e.g. from $9.90 to $29.90 for 10 boards) when you check the box for ENIG. For my board with 0603 SMD components and 0.5mm pitch IC leads HASL is fine.

DRC Rules

When ordering from a PCB fabricator, especially for the first time, it’s important to understand what the limitations are. The SeeedFusion PCB Specification gives a good summary of their manufacturing capabilities. Their capabilities are in line with or better than other prototype PCBs services I have used with 6 mil minimum track width/spacing, 6 mil minimum annular ring and 0.3mm (12mil) minimum drill size.

I particularly liked that they specified their minimum silk screen size (23 mil) as I have made my text too small before now.

Uploading and reviewing design

SeeedFusion only accepts Gerber files. Some other prototype PCB fabs will accept Eagle and KiCad files directly now. This is acceptable as it is a good idea to learn how to generate Gerber files and verify them with a Gerber viewer before sending to a fab anyway. But this is a additional step in the process that might put off people producing their first boards.

They provide a link to EasyEDA’s Gerber Viewer so you can verify your Gerber upload before you submit your order. However I found the size of the rendering a little too small, which makes verification more painful. You can zoom in using the scroll wheel on your mouse, if you have one, but the rendering resolution doesn’t increase, you just get a pixelated image.

Once you have submitted your order you cannot go back and download or view the Gerbers. The ability to download your original Gerbers is especially useful if your boards don’t turn out right. Then there is no wondering which files you actually sent to the fab.

Once you have submitted your order you cannot go back and download or view the Gerbers. The ability to download your original Gerbers is especially useful if your boards don’t turn out right. Then there is no wondering which files you actually sent to the fab.

Fabrication time

I submitted my order to SeeedFusion on a Saturday, received notification that it had being sent to manufacturing on Tuesday and that it had been sent to their shipping agent on Friday. Five business days is a fast turnaround time for a non-express order.

Shipping time

Shipping time obviously isn’t entirely within Seeed’s control, but international shipping is still an important consideration when ordering prototype boards from China.

Seeed offers three shipping options, Registered Post (12 to 22 days), DHL (3 to 5 work days) and FedEx (4 to 8 work days).

There are a lots of variables involved such as the shipping option you choose, local customs processing and local delivery time. US duty should not be required on orders under $800 in value.

I chose Registered Post in order to keep the cost as low as possible. My order showed up on MyUSPS as “shipping label created”, 11 days after being shipped and arrived 4 days later. My second shipment showed up on MyUSPS 13 days after being shipped, but wasn’t marked as in transit for another 15 days and arrived 2 days later. So in my case the international and local shipping times were pretty consistent at around 15 days total, but there was an inconsistent delay at the US boarder, presumably for US customs.

Customer Service

I was unlucky in that my first order had fabrication issues. The silk screen was misaligned and solder mask was missing from the tented vias on one side of the board.

When I contacted customer service they were very responsive. They looked at the original Gerbers, confirmed that it was a mistake on their end and agreed to re-spin and re-ship the boards at no additional cost.

Manufacturing Quality

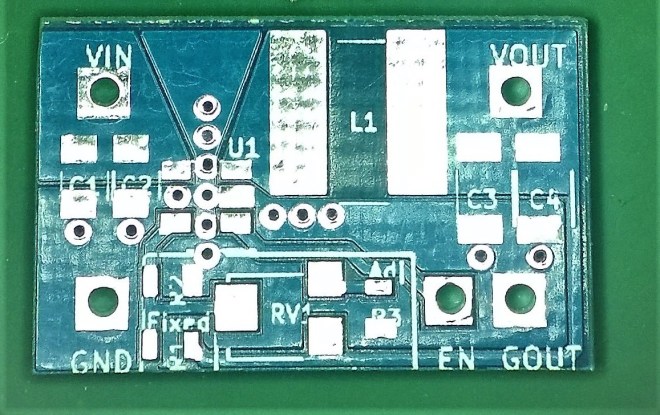

The copper, solder mask and drill accuracy were all very good and the vias were nicely tented.

Every board had a neatly routed outline, with no support tabs to remove, which is very nice.

The HASL surface isn’t as nice as ENIG, but it was perfectly adequate for my circuit.

The silkscreen registration was approximately half a mil too high and to the left on the top of the board. Also small text and graphics are noticeably pixelated. I’ve seen higher resolution silkscreen from other fabs.

An annoying feature is the tracking numbers that get added to every board (10220A-2/400958 above). Seeed decide where on your board to place this number.

Board Testing

I applied solder paste to a PCB with a stencil, populated the components, reflowed on a board heater and hand soldered the header pins.

Everything went smoothly and the circuit (a buck regulator) performed well at max current.