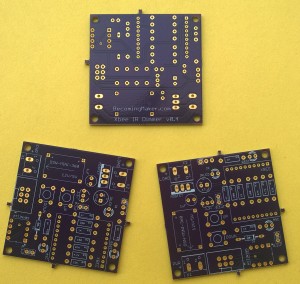

I have received my first printed circuit boards from OSH Park. They look great and I am looking forward to trying them out.

I have received my first printed circuit boards from OSH Park. They look great and I am looking forward to trying them out.

I have designed my own circuits, prototyped them on breadboards and soldered them onto protoboard before, but I really wanted to take the next step and produce a real PCB.

12V LED Dimmer

The PCB circuit is a dimmer control for a 12V LED lighting strip. It provides three means of control:

- Buttons on the device

- An IR remote control

- XBee from a computer

I thought I would make my first boards using through the hole components, but I would like to try surface mount next.

OSH Park ordering experience

These are double sided 2″ by 2″ boards and three boards cost me $19.95 including shipping. OSH Park charge $5 per square inch for three and you can order as many boards as you like, as long as they are in multiples of three.

I ordered the boards and received an email the same day indicating that they were awaiting panelization. OSH Park takes small orders, from Makers like you and me, and groups them together to fill an 18″ x 24″ PCB fabrication panel. When they fill up a panel they send the design file off to the fabricator to be manufactured.

Two days later I received another email telling me that the panel had been sent to the manufacture and they expected to get it back in four days. They even mentioned that there were 36 other orders on the panel and a total of 294 boards.

Three days later they told me that the panel had arrived back from the fabricator and that they expected them to be depanelled and shipped within 48 hours. The panel contains lots of boards connected together by little tabs with three small holes on each side. This enables the individual boards to be broken off the panel. If you look at the picture of my boards you can see some of the tags still attached.

Seven minutes later I received an email telling me that my boards had been shipped. That email included a USPS tracking number.

Two days later a padded envelope containing the boards arrived at my house. So it took seven days from the date that I ordered the boards for them to arrive.

I think that’s pretty awesome price ($19.95) and turnaround time (7 days) for three custom PCBs. As a comparison if I ordered three 2″ x 2″ protoboards from SparkFun they would cost me $15.71 including economy shipping. And it’s nice getting frequent updates on where your board is in the process.

I have shared the board here on OSH Park.

Designing a board

I designed the board using an application called Eagle. CadSoft the company that make Eagle are generous enough to make a freeware version available which is very popular with Makers. You can download it from:

http://www.cadsoftusa.com/download-eagle/

The free version limits your schematic to a single sheet and your board size to 4″ x 3.2″, but that is more than good enough for most Makers.

Eagle takes a bit of getting used to as it is mode based: click to add a component and you’re stuck adding components to your board until you select a different mode from the toolbox on the left. But it’s worth investing in learning it as it opens up a whole new world of possibilities.

There are other circuit board design applications out there, but Eagle is one of the most popular. Also OSH Park will allow you to upload your Eagle files directly, which is nice for a first timer as it cuts out the step of generating Gerber files.

So now I need to find the time to solder some components to the board, with nearly one hundred holes on this board, it might take me a while!